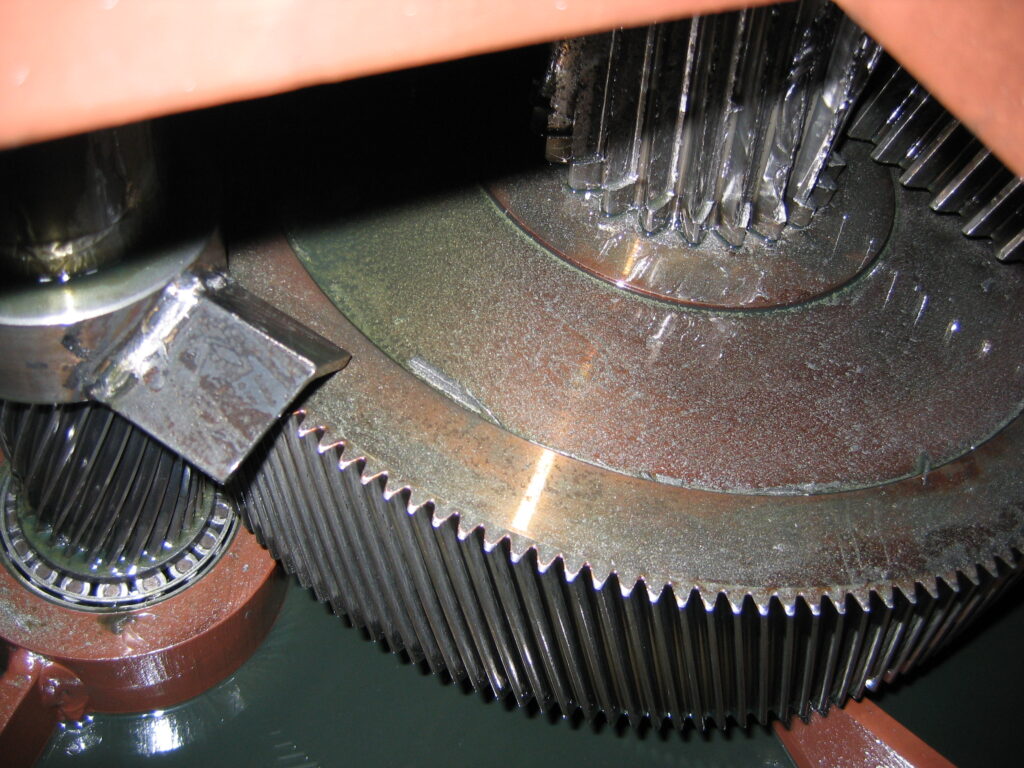

Pinnacle Services offers laboratory analysis of your equipment lubrication properties, as well as suspended contaminants and wear debris. It is important to understand that the lubrication systems in most equipment are only as good as the oil they are using. Daily operation generates wear materials that will accumulate in the system and cause eventual failure. As components wear, the oil that they run on becomes contaminated and eventually fails. The oil analysis program provides a frequency of sampling to be determined by the customer based off variables such as the value of the machinery, environmental factors, etc. The samples will then be analyzed using industry accepted test methods to determine critical parameters such as:

- Viscosity

- Varnish/TAN (Total Acid Number)

- Wear debris

- Corrosion/solids

- Water/moisture content

Using this data we can determine if the oil is in need of replenishing or replacement to protect your equipment from premature failure. This information is vital in protecting your machinery from costly downtime or failure, that costs you money.